Throughout the history of motorcycling, technological progress has never been only about higher speed or stronger performance. From hand-shift gearboxes to diversified transmissions, from carburetors to electronic fuel injection, from mechanical throttles to ride-by-wire, every major breakthrough has fundamentally reshaped how humans interact with machines.

In 1885, Germany witnessed the birth of the first internal combustion motorcycle, the Daimler Reitwagen, proving the feasibility of powered individual transportation. During the First World War, motorcycles began to scale industrial production and gradually explored more complex transmission solutions. After the war, economic recovery and the rise of European, American and Japanese motorcycle manufacturers brought motorcycles into mainstream civilian life. Performance, speed and reliability became central priorities, while motorcycles evolved into symbols of personal freedom, identity and lifestyle expression. Market segmentation, design languages and riding cultures diversified rapidly.

Entering the 21st century, the European Union progressively introduced mandatory ABS regulations, while electronic fuel injection became standard across the industry. Safety, controllability and reliability improved significantly, and the learning barrier for riders was reduced. Motorcycles increasingly shifted from purely mechanical tools toward lifestyle products delivering emotional value. Powertrain development likewise moved beyond peak performance toward higher efficiency, greater controllability and reduced friction between human and machine.

BENDA’s Direction: Reducing Mechanical Burden, Elevating Riding Experience

Against this long historical trajectory, BENDA believes that true progress lies not in sacrificing mechanical character, but in reducing the mechanical complexity placed on the rider while preserving mechanical character and riding pleasure.

From sustained investment in CVT transmissions, to the development of the BEC MK-II electronic clutch, and further to the exploration of single-speed hybrid architecture in the P51 project, BENDA’s technical choices follow a consistent direction: allowing intelligent systems to absorb complexity so that riders can focus on the essence of riding.

Historically, riding a motorcycle demands a high level of mechanical coordination. Throttle control, clutch modulation, gear selection and engine speed management were all part of the riding skillset. While this defines the character of motorcycles, it also raises the entry barrier and limits accessibility. BENDA’s technology exploration gradually shifts rider attention toward balance, trajectory, situational awareness and emotional engagement – the genuine values of riding.

As urban mobility expands, user demographics diversify, and new use scenarios emerge, the industry faces a new question: how to keep the soul of motorcycling while lowering operational friction.

CVT – Continuous Ratios Without Shift Interruption

A Continuously Variable Transmission (CVT) achieves seamless ratio control through a belt connecting a drive pulley and a driven pulley. As engine speed increases, centrifugal weights within the drive pulley move outward, progressively increasing the effective pulley diameter. Simultaneously, the driven pulley spring maintains belt tension and automatically adjusts its effective diameter, allowing the transmission ratio to change continuously.

Because ratio transitions occur smoothly and without discrete gear steps, torque delivery remains uninterrupted, resulting in highly linear and stable acceleration characteristics.

Due to belt durability limits, packaging constraints and thermal load capacity, CVT systems are best suited for motorcycles in the approximately 150-350cc displacement range. Compared with AMT, DCT or quick-shift solutions, CVT architecture naturally avoids shift shock and eliminates clutch operation entirely, significantly reducing the learning barriers. For smaller-displacement motorcycles, it represents a highly efficient and rider-friendly transmission solution.

Traditionally, CVT systems have been concentrated in scooter platforms. BENDA has extended its self-developed CVT technology into cruiser applications, including the Chinchilla 350 CVT and the upcoming Chinchilla 250 CVT and Rock 250 CVT for European and global markets, offering relaxed riding accessibility while preserving classic design appeal.

BEC MK-II – Reducing Manual Control Load by Electronic Clutch

Electronic clutch systems detect the rider’s shifting intent through sensors, with the ECU commanding actuators to automatically disengage and re-engage the clutch during gear changes. The architecture retains a conventional gearbox and mechanical clutch while preserving foot-operated shifting logic, but removes the need for frequent manual clutch actuation.

This approach maintains rider involvement while significantly reducing fatigue and operational complexity. When cost and system complexity are appropriately managed, electronic clutch solutions offer strong scalability across multiple models.

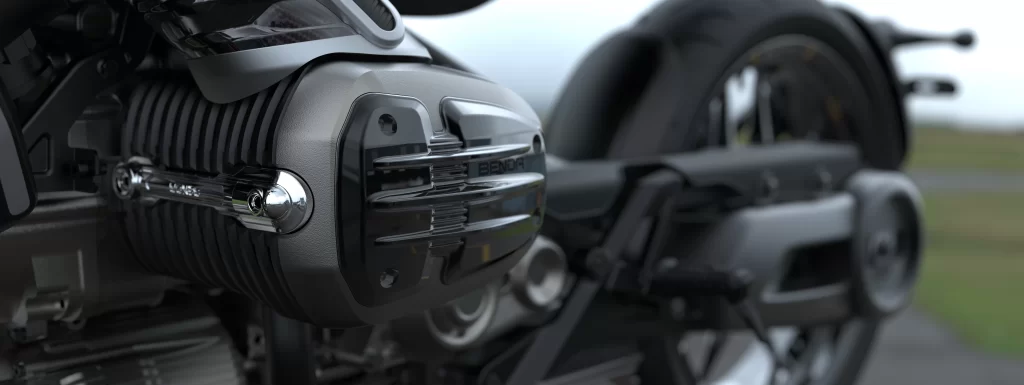

BENDA’s BEC MK-II system has been applied on the Rock 707, offering both electronic and manual clutch modes, allowing riders to select between convenience and traditional engagement based on preference. The model is expected to enter European and global markets in the second half of 2026. BENDA continues to expand development of the BEC MK-II platform for broader product integration.

Hybrid Power – Reducing Dependence on Mechanical Gear Ratios

At EICMA 2025, BENDA unveiled the 250cc hybrid naked bike P51 and continues to advance its validation and production readiness.

In the P51 hybrid architecture, the electric motor inherently delivers a wide operating speed range, strong low-speed torque and continuously controllable output. This allows the powertrain, in most operating conditions, to significantly reduce reliance on multi-ratio mechanical gearboxes. Unlike conventional internal combustion engines that require gear ratio multiplication to match different operating demands, hybrid systems leverage motor-engine coordination to deliver smoother and more direct torque control.

Rather than merely simplifying transmission mechanisms, this approach reshapes the power source architecture itself, reducing the necessity of frequent gear changes and improving drivability, controllability and smoothness. Through integrated system control, the P51 achieves 3.7 seconds from 0-100 km/h while maintaining approachable and intuitive handling characteristics.

A Unified Direction and Industry Perspective

These technologies are not isolated choices, but part of a unified technical trajectory: transferring complexity from the rider to intelligent systems in order to deliver clearer feedback, smoother operation and higher confidence.

From an engineering perspective, this evolution mirrors trends seen in automotive and aerospace industries, shifting from mechanically intensive control toward system intelligence, human-machine decoupling and human-centred architecture. The objective is not to diminish rider engagement, but to expand the boundaries of safety, accessibility and experience quality.

BENDA’s technology exploration is therefore not about chasing novelty, but about shaping the next stage of motorcycle evolution, enabling machines to adapt to humans, rather than forcing humans to adapt to machines.

Riding becomes not merely a technical exercise, but a more mature, expressive and liberated form of mobility.